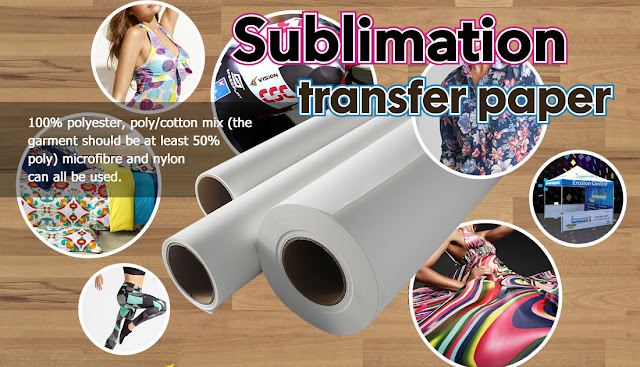

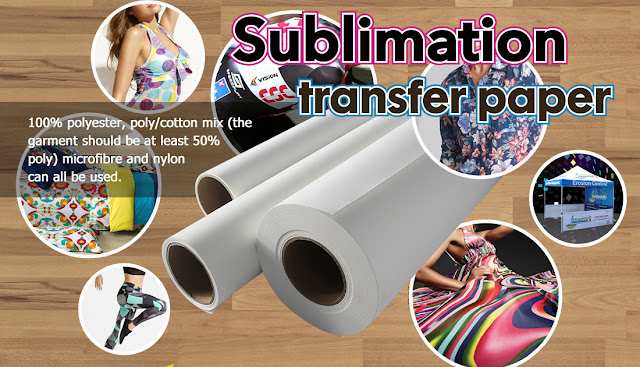

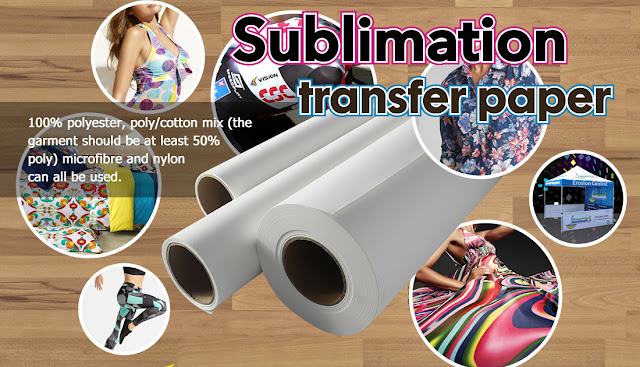

Instruction of sublimaiton paper

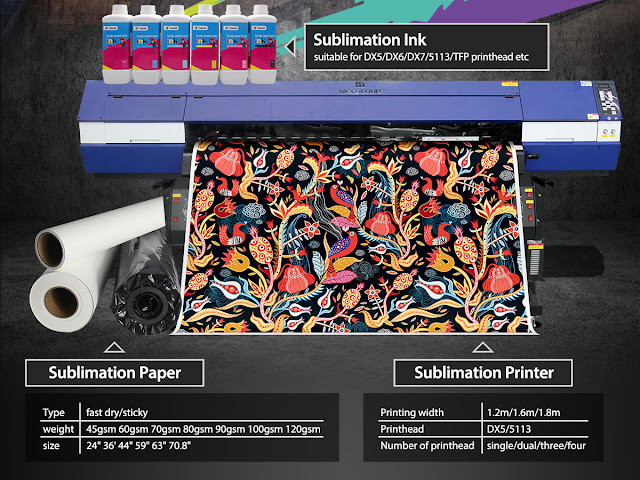

Vison Paper offer dye sublimation transfer paper . Weight 45gsm, 60gsm, 70gsm, 80gsm,90gsm,100gsm, 120gsm. And, the large format printing papers like 45gsm 1.62*1000m~16000m. 60gsm 1.5/1.52/1.6/1.62*9000m~10000m. 70gsm 1.118~1.88*9000m~10000m. 80gsm 1.118~1.88*7000m~8500m. 90gsm 1.118~1.88*5000m~7000m. 100gsm 0.85~1.88*5000m~7000m. Sublimation transfer printing on Sublimation fashion apparels, Sublimation sportswear, Home furnishing, Gaming table, Sublimation frame, Soft signage, Sublimation gifts and Sublimation on hard surface. How to do sublimation(use heat press machine)? 1.Printing pattern onto sublimation paper. 2. Use heat press machine to transfer pattern from sublimation paper onto fabric. APPLICATION T-shirt、soccer jersey、pillows、roller fabric、textile、cutting pieces、carvas、carpet、glass、aluminum sheet、mug、cap、curtain、tent、seven piece puzzle... Website: www.itransferpaper.com Email: vision@itransferpaper.com Whatsapp:+86-17321