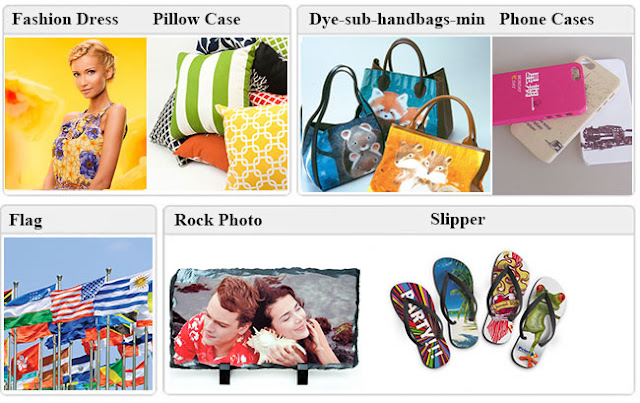

Here are some of the material possibilities you have with dye sublimation printing

Sublimation transfer is the portrait, landscape, text and other graphic use with sublimation

transfer ink inkjet printer to mirror print on the sublimation transfer inkjet paper, and then

through the thermal transfer device heating to About 200℃, so that the heat transfer paper

on the thermal transfer ink sublimation into the substrate, so that the color image on the

paper realistic transfer to the textile, porcelain cup, porcelain plate, porcelain, metal and

other materials on a new technology.

Here are some of the material possibilities you have with dye sublimation printing:

Rigid Substrates – No longer limited to just fabric substrates, there is a wealth of variety in product and promotional possibilities available. New polymer treated materials have been developed specifically for dye-sublimation applications that include aluminum, brass, glass, fiberglass, acrylic, plastic and hardboard sheet materials.

Rigid Products – The rigid “blank” products that are widely available include, mouse pads, key chains, smartphone cases, pet bowls, light switch plates and more. These are easily sublimated and represent fantastic additions to the range of custom branding items your business can offer.

Soft-Signage – Create on-demand, high-impact POP, tradeshow and interior signage. The sublimation paper transfer process is fast and ideal for time-sensitive promotions.

Fabrics – Choose from a range of 100% polyester fabrics. The choices of fabrics come in two distinct types:

1.Woven texture for sturdy and hardwearing banner stands, exterior banners, exterior signage and upholstery

2.Knit material that drapes and flows more naturally, for custom apparel, indoor flags and banners, photographic backdrops and table covers.

Sports and Fashion Apparel – Everything from T-shirt and cycling jerseys to handbags and baseball caps is a possibility. The ever-growing popularity of sports and fashion apparel opens up new sublimation opportunities everyday.

Photo Printing – From personalized gift items such as magnets, wall mounts and photo-apparel to photo backdrops, sublimation is perfect for delivering high quality photographic images to a wide range of markets.

Ceramic Tiles – Interior designers and decorators can create customized ceramic tiles for kitchens, bathrooms, foyers, museums, restaurants, and offices.

All the materials listed above are polymer suitable for heat transfer or available as product “blanks” for immediate heat transfer. In addition, there are also pre-treatment options available to the user that enables printing on an even broader spectrum of items.

Sublimation process:

1. Design your image with Photoshop , CorelDRAW, or Adobe lllustrator.

2. After your design if finished , print your image (mirror printing)with an ink-jet printer(like

Epson, Mimaki etc) that use sublimation ink, with sublimation transfer paper.

3. When the sublimation paper completely dries, transfer the image to the substrate with the

heat press(Flat or Roll heat press, mug heat press, 3D heat press etc). The whole process is

finished.

Here is the process of how to make a sublimated t-shirts using jumbo roll sublimation paper

Vision Digital Printing Co.,Ltd,founded in 2008 , is a professional sublimation transfer paper suppliers.Our jumbo roll sublimation paper is widely used on hometextile and garments.wecome to contact us:

评论

发表评论

see more on our web www.itransferpaper.com