Sublimation for day to day

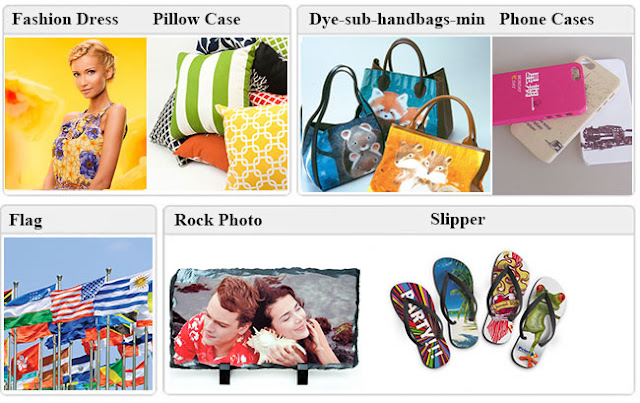

In addition to its high quality and color fidelity, the advantage of sublimation is that it offers a high level of customization that attracts all kinds of audiences, especially younger generations. The sublimation is one of the best positioned printing techniques in the printing industry and the large number of commercial sectors it serves, including advertising and recently fashion design stands out. The growth of this technique has been so naturally and progressive that even brands of equipment have been surprised to discover that their customers adaptations made to traditional machines to print certain products. Against this background, sublimation has diversified and today it is possible to print almost any object using this technology. Customizing the highest level in past years was the preferred sublimation printing technique for souvenirs and clothing for advertising purposes. However, when the public became familiar with the technique he began to apply it...