Why to choose mecolour Pneumatic Double-station Heat Press Machine ?

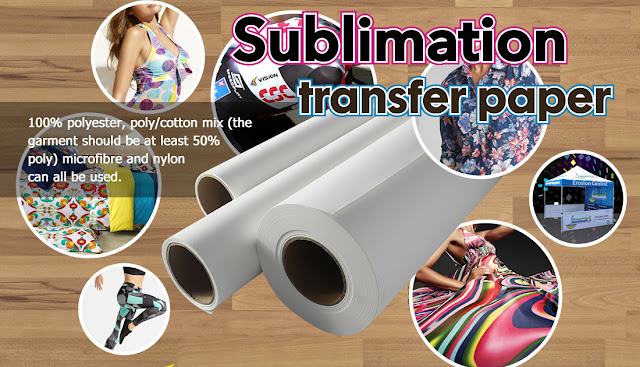

The sublimation market is a large market that has advanced technological methods and resources for the business of printing on photo products and fabrics. Many people want to enter the sublimation area because it is an area with enough possibility of profits, through it is possible to produce several materials in large quantity using large machinery. One of the large format heat press machines that Mecolour works on is the Press 80x100cm and 120x150cm, they have two flat plates that are moved automatically or manually. With them it is possible to sublimate synthetic fabrics for the manufacture of flags, shirts, uniforms and all fabrics containing at least 65% polyester. The pneumatic press is efficient and effective because it prevents the resublimation (ghosting), in addition, it sublimates up to 85 pieces per hour. Let's count, To use a common press requires 5 to 10 minutes to heat it up to 200 ° C (temperature required to sublimate fabrics)...